Brown glass forming processes

1. raw material

Silica sand, soda ash, limestone, and others.

2. batch house

Weighing and mixing of raw materials, and transport to the hopper at the melting furnace.

3. Melting

Melting of mixed raw materials about 1,550℃ in the melting furnace.

4. Feeding

Feeding of glass job at optimum temperature suitable to bottle weight and shape is fed into a bottle-forming machine via the feeder.

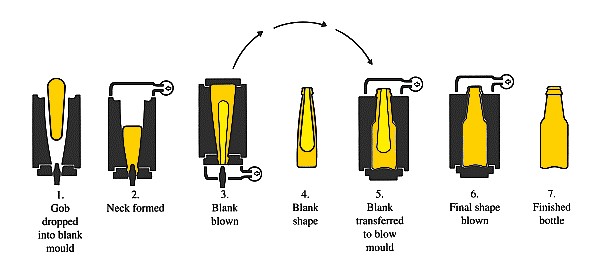

5. Forming

Forming of bottle by the glass bottle-forming machine for designed bottle shape.

6. Annealing

Annealing of bottles as they leave the glass bottle-forming machine

7. Inspection

After annealing in the lehr, a bottle is strictly checked on Automatic inspection machine and inspect each bottle to confirm quality by skilled technicians.

8. Additional processing

Decal or silkscreen; Frosting; Spraying; Electroplating.

9. Packing and shipment

Bottles are packed according to their destination, then shipped.